| Home | Retour | Contact |

|

Technology for continuous heat treatment of bulk material |

|

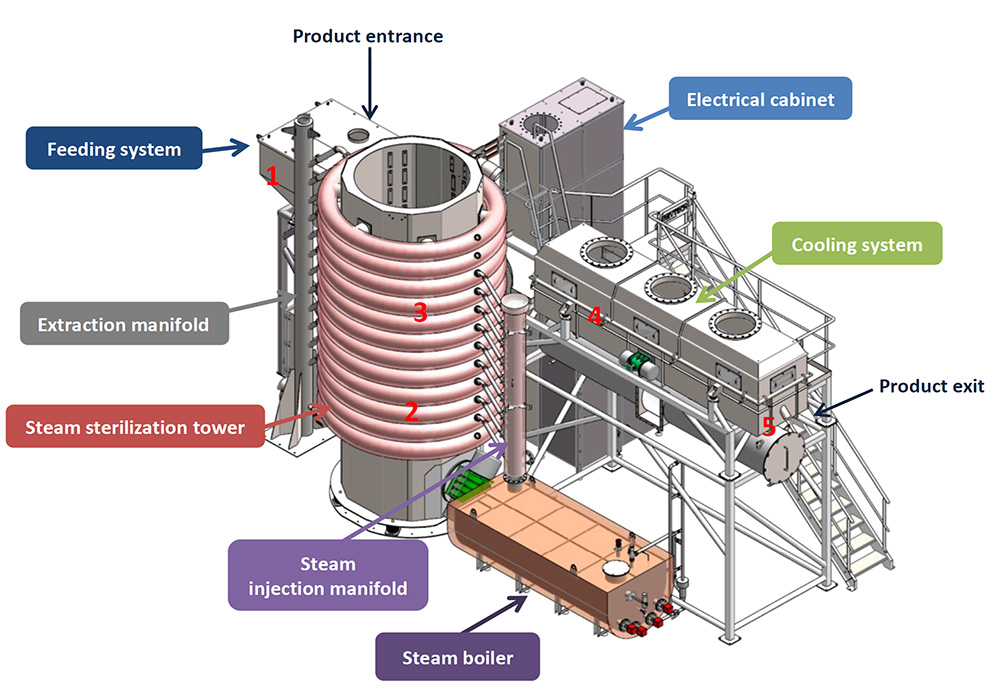

The French company

REVTECH Process Systems has

developed and successfully launched a new

REVolutionary TECHnology for

continuous heat treatment of bulk solid, free flowing powdered,

granulated, and small-sized materials. This modern technology is

characterized by gentle processing of raw materials, economical and

environmentally friendly operation, easy cleaning and maintenance.

Further advantages of this technology are: the possibility to work

precisely controlled in a wide temperature range from 50 ° C to 800

° C, in a continuous process with residence times from a few minutes

to a few hours and outputs of 200 - 5,000 kg / h. The danger of a

dust explosion or a fire outbreak is largely completely eliminated

by the unique design. The REVTECH

technology is based on a spirally stainless-steel spiral tube

mounted on a frame. The tube is heated by means of electrical

resistance to the required temperature. At the bottom part of the

frame, two vibration motors are applied. The entire system stands on

flexible rubber compensators and is firmly anchored in the ground by

means of screws. The motors subject the entire system to directed

vibrations. The treated material is moved by the vibrations inside

the tube from bottom to top and it is treated at the same time. |

|

|

This innovative technology is sucessfully used in the food, feed, agricultural, chemical and other industrial areas. |

|

Continuous heat treatment - drying,

roasting and pasteurising of: Nuts -

hazelnuts, walnuts, cashew nuts,

macadamia, para- and pecans,

peanuts, almonds,

pistachios, with or without shell, whole or sliced

Kernels - pumpkin seeds, sunflower seeds,

pine nuts Grains

and flakes - cereals, buckwheat,

amaranth, corn, millet, malt Seeds

- flax seeds, sesame seeds, hemp seeds Beans

- soy, cocoa, coffee, legumes

Advantages: uniform roasting in the wide

range of taste and colour shades, gentle treatment without

mechanical action, high microbiological purity, low energy

consumption, low gas emissions, easy product change and cleaning |

|

|

|

Continuous heat treatment - drying, toasting and roasting of:

various extrudates, small biscuits

pieces, breadcrumbs, crumbles and premixes for bakery fillings

Continuous coating

- with fats and oils, with dispersions of aromas and spices in oils,

with aroma and colour emulsions. Advantages over direct roasting in

oils, no heat damage, no bad smell, no bad taste Continuous hot air expansion of pre-treated cereal grains and various seeds and beans, of indirectly expanded extrudates of breakfast cereals and snacks |

|

|

|

Continuous hydrothermal treatment - for microbiological reduction of spices, dried herbs and medicinal herbs, teas and tea blends including fruit teas by combined treatment with heat and steam. The steam is dosed in small quantities, so that the effect mainly on the surface of the product happens. It does not diffuse any vapor into the product nor does it condense on its surface, and it does not affect the sensory properties of the materials. Unique technology with high efficiency, gentle treatment with low energy consumption and less cleaning effort. Continuous hydrothermal treatment - of poppy seeds to stabilize against enzyme-induced oxidation processes. Unique technology for reduction of morphine content in poppy seeds and stabilization in one step. |

|

|

|

Continuous heat treatment -

toasting and roasting of cereal seeds,

flours, beans and lupines, various milling fractions, germs, hulls,

proteins, hulls and fibres or seedlings with the aim: - To

stabilize them by inactivating enzymes - To

reduce the microbiological contamination -

To

optimize their rheological properties by

physical modification of the starch fraction (recrystallization) or

of the proteins (denaturation) Continuous heat treatment - intensive roasting of cereal flours to set various shades of toasted flavour and roast colour for use as colouring and flavouring foods. |

|

|

|

Stabilization of oilseeds and beans by thermal inactivation of enzymes -

Oilseeds (sunflower, pumpkin,

flax, sesame, poppy, pines and others) - beans (soy, chickpeas,

cocoa and others) - nuts (walnuts,

hazelnuts, cashews, pistachios and others)

-

Wheat germ (wheat, corn and

others) have a high oil content with a high content of unsaturated

fatty acids. These are susceptible to enzymatic degradation and

subsequent oxidation by atmospheric oxygen. This in turn leads to

unpleasant taste and smell of stale oil. By heat treatment, often

combined with a small amount of steam, the enzymes are inactivated

and the shelf life and sensory quality of the products is prolonged

without significantly altering the taste and odour. |

|

|

|

Innovative and highly

effective technology for reducing morphine in poppy The

content of morphine in blue poppy is a standard strictly followed by

the criterion for the use of poppy seeds for food purposes. Poppy

with a higher morphine content in poppy seeds carries microscopic

dust particles from the plant straw, which gives it a higher

morphine content than allowed by the standard. The only option is to

remove these fine dust particles in an effective manner that does

not affect poppy sensory properties and does not require special

approval for handling narcotic drugs. Our technology can lower poppy

morphine content below 10 mg / kg raw material (10 ppm). The removed

morphine is neither concentrated nor captured and no special

operating permits are required. |

|

|

|

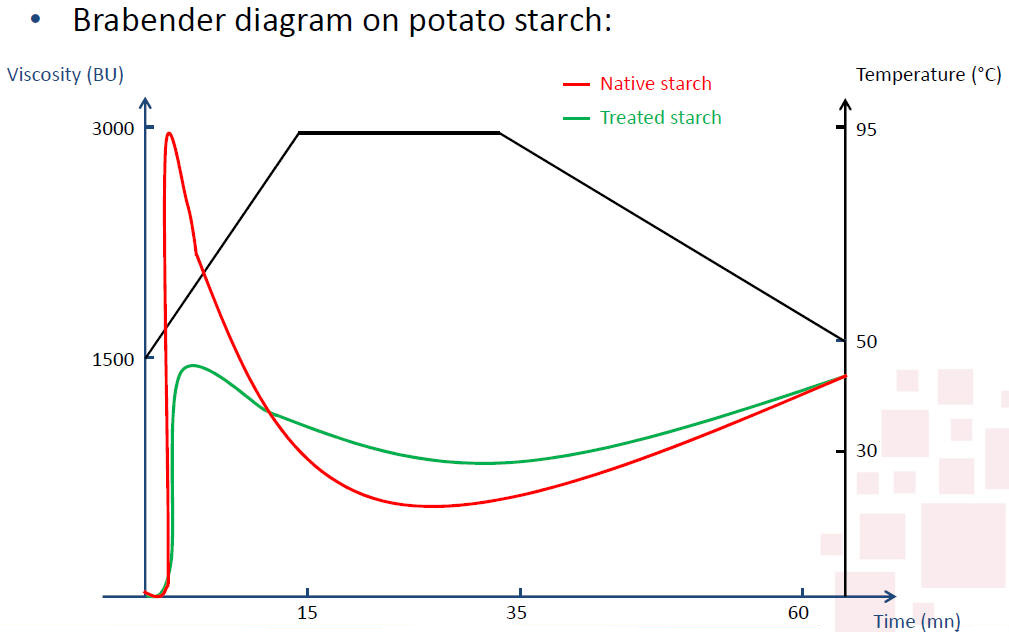

Continuous physical reactor

for the modification of starches in a

dry process with the aim of optimizing their application properties,

in particular for use in clean label and organic products.

Especially suitable for the known alkaline catalysed roasting

processes and also for the production of resistant starch and

dextrin of any kind.

Continuous chemical reactor -

for carrying out chemical modifications to starches in a dry

process. Long reaction times, narrow reactor space, precise

temperature control, continuous material movement and mixing and

long residence times offer new potential for dry reactions of starch

and other polysaccharides.

|

|

|

|

Continuous reactor for

various processes on bulk solids: Calcination -

Metal oxides, silicic acid compounds,

bentonites, pharmaceutical waste Sintering -

metal oxides, zeolite Thermal desorption - catalysts,

contaminated soil, foundry sands, synth. Rubber, cork, gas-solid

reactions - catalyst activation, regeneration, preparation Ultra-drying - H2O <0.1%

- alumina, zeolite and other molecular

sieves, glass microspheres, corrosive powders Pyrolysis -

wood, agricultural waste Preheating -

sodium chlorate, drying - sand, PET,

clay, plastic granules Crystallization - plastics and products from the same, sterilization - pharmaceutical products |

|

|

|

Roasting oak wood and other wood chips -

modern, continuous and ecological

production of roasted oak chips as well as other wood chips that can

be used to process wines, spirits, liqueurs, beer and the like.

Pyrolysis of organic materials - production

of biochar -

Continuous process of pyrolysis of

organic materials -

Simple and safe handling - Easy trapping of pyrolysis gases,

possibility of heating - The

advantageous use of non-traditional wastes such as walnut shells and

the like. -

Economic and ecological process without risk of fire and explosion - A preferred method for the production of biochar and activated carbon of high purity

|

|

|

|

Are

you looking for an innovative, economical and environmentally

friendly technology for drying, roasting, pasteurizing or

heat/moisture treatment for your processing or production process?

Contact us! We

support you by information and

design a tailor-made solution for

you. |

|

| Home | Retour | Contact |