| Home | Retour | Contact |

| Machines and installations for mixing, homogenizing, wetting, agglomerating and coating. |

|

Horizontal uniaxial mixer - is suitable for mixing powdery to granular materials. The mixer works on the principle of counter-movement of the material by rotating og specially designed spiral mixing arms, which ensures a very efficient mixing. The mixing can be done at higher revolutions to achieve a quick homogeneity effect or at lower revolutions to save the material. The mixer is made on request in stainless steel AISI 304 or higher quality. The mixers are mounted on metal frame. Smaller mixers can be mobile on wheels, with a switch box on the frame for manual control. The mixer can also be equipped with an automatic control and built to a complete mixing line. The mixing shaft is driven by an electric motor via a gearbox. The engine speed is controlled by frequency converter. The mixing bin has a hinged cover on the top for easy cleaning. The mixing bin is equipped with a safety switch and two gas-filled arms to easily open and close the lid. There is an outlet on the bottom, which is closed by an electropneumatic valve. The mixer is supplied in standard volumes of 190 - 340 - 550 - 980 - 1500 - 2000 - 3500 litres with an engine power between 2.2 - 22 kW. |

| |

|

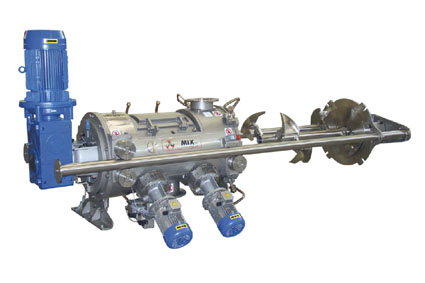

Single-shaft horizontal mixer with plough mixing elements - suitable for fast and homogeneous mixing of powdered to granular materials. The principle of mixing is to swirl the material with the moving plough-shaped mixing elements, creating a fluidized bed and mixing the streams of material together. The mixing is very intense, but also mechanically stressing the material. This mixer is preferably suitable for granulating powder materials, during which agglomeration liquid is sprayed onto the material. The powder is agglomerated in lumps and the excess moisture is either dried after discharge from the mixer or directly in the mixer by indirect heating of the material by means of a double jacket of the mixing vessel or even by connection to a vacuum pump. If agglomeration is undesirable, rotating cutterheads are used to break up the agglomerates. The mixer can also be used as a chemical reactor. Also available in ATEX conform design. Material stainless steel of the required quality according to customer requirements. |

| |

|

Vertical uniaxial conical mixer suitable for mixing from powder to granular structured materials. It works on the principle of material movement by spiral mixing arms, which moves the material along the mixer wall from bottom to top, and the material falls free in the middle of the mixer down. Mixing is very efficient and material friendly. The mixer is filled via a filling opening on the lid. It can also be equipped with a hopper for emptying of sacks. The speed of the mixing axis can be controlled by the frequency converter. Mixing tank volume 100 l - 3000 l can be delivered. The mixers are made from mild steel or on customer request from stainless steel. The mixing process is characterized by a high degree of homogeneity. The spiral blade is moving close to the mixing bin wall and prevents the material sticking to the bin wall. |

| |

|

Horizontal Drum Mixer - works on the principle of a rotating drum with passive mixing elements inside of the drum. The drum is mounted on 4 support rollers. On each side of the drum, a special seal is attached, which connects the inlet and outlet systems dust-tight with the drum. The orientation and shape of the mixing elements is designed so, that the drum can be completely emptied after opening the opening the outlet valve (> 99.5%). This valve is operated by compressed air. There are three large openings with doors on the drum, dustproof covering these. The mixer is mounted on a support frame. The mixer is filled on one side via the filling opening and emptied on the other side through the emptying opening. The mixer can be equipped with a simple control, or with fully automatic computer control system.

Advantages: - Short mixing times - No mechanical load on the

mix - Easy cleaning and

maintenance - Very low energy requirement

Batch size 10 - 100% of the mixer volume |

| |

|

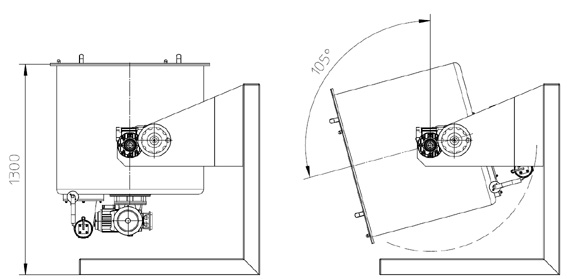

Vertical single shaft mixer -

suitable for mixing from powdery to granular materials. It works on the

principle of material movement by spiral mixing arms, which are moving

the material along the mixer wall upwards, and the material falls free

in the middle of the mixer downwards. Stirring is very efficient and

material friendly. The mixer is filled from the top and the finished

product is controlled discharging by a screw at the bottom of the mixing

vessel. The mixing vessel is fixed on a metal frame. For a simpler and

well cleaning, the container can be turned over. A practical solution is

that the mixing tank can be lifted by a hydraulic system. When the

container is filled, it is lifted, and after mixing the product, a

weighing funnel on weighing cells is tipped underneath, and the balanced

amount of product can be semi-automatically filled in the package.

Weighing is controlled either by a Siemens microprocessor system or by the

electronic balance DINI AGRO.

View into the mixer Mixer on frame with manual tilting |

| |

Container mixer NAUTA mixer |

Continuous single shaft mixer | |

|

Are

you looking for an efficient, economic and ecological technology for

mixing, granulating, applying of liquids when mixing for your processing

or production process? Contact

us!

We provide you

with information and offer a customized

solution. |

|

| Home | Retour | Contact |